#Programmable Logic Controller Market Insights

Explore tagged Tumblr posts

Text

Programmable Logic Controller Market Anticipated to Grow Owing to Automation Demand

The Global Programmable Logic Controller Market is estimated to be valued at USD 12.40 Bn in 2025 and is expected to exhibit a CAGR of 4.3% over the forecast period 2025 to 2032. Programmable logic controllers (PLCs) represent a critical segment of industrial automation technology, designed to monitor inputs, make logic-based decisions, and control outputs in real time. Functioning as ruggedized computers, PLCs offer unparalleled reliability, scalability, and flexibility across manufacturing, automotive, food & beverage, and oil & gas sectors. In the context of Industry 4.0, where digitalization and connectivity drive operational excellence, Programmable Logic Controller Market Insights serve as the foundational element for implementing smart factories, predictive maintenance practices, and energy management systems. By providing advanced diagnostics, traceability, and easy programming through ladder logic or structured text, these controllers reduce downtime, lower maintenance costs, and enhance business growth by boosting overall equipment effectiveness.

Get more insights on,Programmable Logic Controller Market

#Coherent Market Insights#Programmable Logic Controller#Programmable Logic Controller Market#Programmable Logic Controller Market Insights#Ladder Logic

0 notes

Text

Bitcoin: The First Truly Autonomous System

Imagine a system so resilient, so incorruptible, that it doesn’t require human oversight to function. A financial network that operates in perfect harmony, never stopping, never asking for permission, never needing a bailout. While governments rise and fall, while corporations collapse under mismanagement, and while even artificial intelligence still needs human programmers to shape its course, Bitcoin just runs.

It doesn’t take weekends off. It doesn’t panic in a crisis. It doesn’t wait for approval from any central authority. It is the first—and only—truly autonomous financial organism.

A Machine That Governs Itself

In traditional finance, systems crumble when humans fail. Banks miscalculate risk and go under. Central banks print money recklessly, causing inflation that eats away at people’s savings. Governments manipulate markets to serve political interests. But Bitcoin stands apart. It exists without rulers, without committees, without corruption. Its only master is its code—an immutable set of rules that no single entity can alter.

There is no CEO of Bitcoin. No government controls its issuance. No banker decides who can access it. Bitcoin is pure logic, a trustless system where transactions are verified by mathematics rather than human opinion. Every 10 minutes, a new block is added, and the network continues forward, unbothered by the chaos of the human world.

AI Needs a Master—Bitcoin Does Not

Some might argue that artificial intelligence is the pinnacle of autonomous technology, but AI still needs human intervention. It must be trained, maintained, and aligned with human interests—or risk spiraling into unintended consequences. AI can be shut down, reprogrammed, or manipulated by those in power. Bitcoin cannot.

Even Central Bank Digital Currencies (CBDCs), which governments will claim to be “modernized” digital money, will be programmed with rules dictated by bureaucrats. They will be surveilled, censored, and controlled. Bitcoin, on the other hand, is self-governing. Its ledger is open, its supply is fixed, and its rules are enforced by an unstoppable network of participants spread across the globe.

A Neutral System in a World of Bias

Bitcoin doesn’t care who you are. It doesn’t care about your nationality, your political beliefs, or your economic status. It treats everyone equally, offering the same rules and the same access. In a world where financial systems are weaponized—where bank accounts are frozen due to politics, where hyperinflation robs entire populations of their wealth—Bitcoin remains untouched. It is the last truly neutral system, offering financial sovereignty to anyone who seeks it.

The Birth of Digital Sovereignty

Bitcoin is more than just money. It is the blueprint for a future where autonomous systems can outlast the failures of human governance. Its ability to function without oversight, without corruption, and without centralized control makes it unlike anything that has ever existed before.

As long as a single node runs, Bitcoin lives. No government decree, no economic collapse, no act of war can erase it. It is the first of its kind—a system that does not ask for permission, does not yield to power, and does not stop. It is autonomy in its purest form.

Take Action Towards Financial Independence

If this article has sparked your interest in the transformative potential of Bitcoin, there’s so much more to explore! Dive deeper into the world of financial independence and revolutionize your understanding of money by following my blog and subscribing to my YouTube channel.

🌐 Blog: Unplugged Financial Blog Stay updated with insightful articles, detailed analyses, and practical advice on navigating the evolving financial landscape. Learn about the history of money, the flaws in our current financial systems, and how Bitcoin can offer a path to a more secure and independent financial future.

📺 YouTube Channel: Unplugged Financial Subscribe to our YouTube channel for engaging video content that breaks down complex financial topics into easy-to-understand segments. From in-depth discussions on monetary policies to the latest trends in cryptocurrency, our videos will equip you with the knowledge you need to make informed financial decisions.

👍 Like, subscribe, and hit the notification bell to stay updated with our latest content. Whether you’re a seasoned investor, a curious newcomer, or someone concerned about the future of your financial health, our community is here to support you on your journey to financial independence.

📚 Get the Book: The Day The Earth Stood Still 2.0 For those who want to take an even deeper dive, my book offers a transformative look at the financial revolution we’re living through. The Day The Earth Stood Still 2.0 explores the philosophy, history, and future of money, all while challenging the status quo and inspiring action toward true financial independence.

Support the Cause

If you enjoyed what you read and believe in the mission of spreading awareness about Bitcoin, I would greatly appreciate your support. Every little bit helps keep the content going and allows me to continue educating others about the future of finance.

Donate Bitcoin:

bc1qpn98s4gtlvy686jne0sr8ccvfaxz646kk2tl8lu38zz4dvyyvflqgddylk

#Bitcoin#Decentralization#FinancialFreedom#Autonomy#SelfSovereignty#CryptoRevolution#SoundMoney#DigitalGold#BlockchainTechnology#BitcoinFixesThis#MoneyOfTheFuture#EconomicFreedom#TheFutureIsNow#Hyperbitcoinization#BitcoinPhilosophy#blockchain#financial education#digitalcurrency#finance#globaleconomy#financial empowerment#unplugged financial#cryptocurrency#financial experts

4 notes

·

View notes

Text

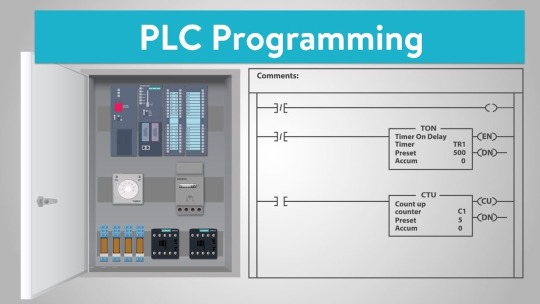

The Basics of PLC Programming: A Comprehensive Guide

If you're interested in the field of industrial automation or looking to enhance your skills in the industry, PLC programming is a crucial skill to possess. Programmable Logic Controllers (PLCs) are widely used in manufacturing and process control systems, and understanding how to program them is essential for ensuring efficient and reliable operation.

In this comprehensive guide, we will explore the basics of PLC programming, covering key concepts and providing valuable insights for beginners in the field.

1. What is PLC Programming?

PLC programming involves creating a set of instructions that control the behavior of a programmable logic controller. PLCs are used to monitor inputs from various sensors, process that data, and execute specific actions based on pre-defined logic. By programming a PLC, you can automate complex industrial processes, making them more efficient and reliable.

2. Why Learn PLC Programming?

PLC programming offers numerous benefits in the industrial automation realm. By acquiring this skill, you can:

Improve productivity: PLCs enable automation, reducing manual labor and increasing overall productivity.

Enhance efficiency: Automation minimizes human error and optimizes processes, resulting in higher efficiency levels.

Facilitate troubleshooting: Understanding PLC programming allows you to diagnose and fix issues efficiently, minimizing downtime.

Expand career opportunities: PLC programming expertise is in high demand, with many industries seeking professionals with these skills.

3. PLC Programming Training Courses:

To learn PLC programming effectively, it's essential to enroll in specialized training courses. These courses provide a structured curriculum, hands-on exercises, and expert guidance. Here are a few key aspects to consider when choosing a PLC programming training institute or center:

Comprehensive curriculum: Look for a training program that covers both theoretical concepts and practical implementation.

Experienced instructors: Ensure that the training institute has qualified instructors with industry experience to guide you effectively.

Hands-on practice: Practical exercises and projects are crucial for gaining proficiency in PLC programming.

Industry relevance: Verify that the training course aligns with current industry standards and practices.

Certification: Opt for courses that offer certifications upon completion, as they enhance your credibility in the job market.

4. Key Concepts in PLC Programming:

Ladder Logic: Ladder Logic is the most commonly used programming language for PLCs. It employs graphical symbols to represent logic functions and control sequences, making it easy to understand and implement.

Inputs and Outputs: PLCs interact with the physical world through inputs (sensors) and outputs (actuators). Understanding how to read inputs and control outputs is fundamental in PLC programming.

Programming Instructions: PLCs execute a set of instructions to perform desired operations. These instructions can include timers, counters, mathematical operations, logic gates, and more.

Program Execution: PLC programs are executed in a cyclical manner. The PLC scans inputs, processes logic, updates outputs, and repeats the cycle continuously.

5. Programming Tools and Software:

PLC programming software provides an interface to create, edit, and debug programs. Familiarize yourself with popular software tools such as Siemens TIA Portal, Allen-Bradley RSLogix, or Schneider Electric Unity Pro, as they are widely used in the industry.

Conclusion:

PLC programming is an essential skill for individuals aspiring to succeed in the field of industrial automation. By learning the basics of PLC programming, you open up a world of opportunities to streamline processes, enhance productivity, and contribute to the advancement of various industries. Enroll in a reputable PLC programming training institute or center, explore the key concepts, and start your journey towards becoming a proficient PLC programmer.

#plc-programming#learn plc programming#plc programming training#plc programming courses#plc training course in india

3 notes

·

View notes

Text

Programmable Logic Controller Market Set to Hit US$ 17.2 Bn with Strong Demand from Smart Industries

The global programmable logic controller (PLC) market, valued at US$ 11.6 Bn in 2022, is forecast to grow at a CAGR of 4.7% between 2023 and 2031, reaching a market value of US$ 17.2 Bn by the end of 2031, according to the latest industry insights. This growth is propelled by a surge in demand for industrial automation, smart manufacturing, and increased integration of the Industrial Internet of Things (IIoT).

Market Overview: A programmable logic controller (PLC) is a digital computer used to automate electromechanical processes, particularly in manufacturing environments. These devices are integral to the efficient operation of assembly lines, robotic devices, and any activity requiring high-reliability control and ease of programming. With increasing adoption across automotive, food & beverage, chemical, energy & utility, and construction industries, the global PLC market continues to expand in scope and application.

Market Drivers & Trends

The rising trend of smart factories and Industry 4.0 is among the most significant growth drivers. Manufacturers are increasingly adopting automation to reduce operational costs, improve productivity, and enhance precision. PLCs play a critical role in this transformation by allowing control over complex industrial processes with minimal human intervention.

Additionally, the growing need for data-driven decision-making, along with advancements in machine learning and artificial intelligence, is leading to deeper integration of PLCs in industrial settings. As automation becomes central to production and operational strategies, the demand for PLCs is expected to surge further.

Latest Market Trends

One of the most notable trends is the shift toward modular PLCs, which accounted for over 68.2% of the market share in 2022. These PLCs are gaining popularity due to their scalability and suitability for large-scale, complex automation tasks. Modular systems offer higher flexibility, can handle thousands of inputs/outputs, and support multitasking environments—making them ideal for high-volume manufacturing operations.

Another trend is the miniaturization of PLCs, which supports their deployment in compact systems and small machinery, especially in consumer electronics and smaller automated units.

Key Players and Industry Leaders

The competitive landscape is fragmented yet dominated by global industrial automation giants. Leading companies in the PLC market include:

Siemens

Rockwell Automation

Mitsubishi Electric Corporation

Schneider Electric

OMRON Corporation

ABB

Panasonic Corporation

Bosch Rexroth Corporation

Delta Electronics, Inc.

Honeywell International Inc.

These companies continue to drive innovation through strategic partnerships, R&D investments, and product expansions to enhance their market share and global footprint.

Recent Developments

Crouzet, in December 2022, launched Millennium Slim, the slimmest PLC in the world, tailored for compact industrial applications.

In July 2022, OMRON Corporation introduced the CP2E Micro PLC, designed for smaller devices and capable of data collection and machine-to-machine communication. This supports low-cost automation solutions for small- and mid-sized enterprises.

Electronics Corporation of India Limited (ECIL) released its own PLC and SCADA software in May 2022, targeting industrial control applications in Indian manufacturing ecosystems.

These product introductions underline the market’s commitment to technological advancement and responsiveness to evolving industrial demands.

Market Opportunities

The expansion of material handling systems, especially in e-commerce logistics, warehousing, and food processing industries, presents substantial growth potential for PLC integration. In material handling, PLCs streamline storage, movement, and tracking—drastically improving throughput and inventory management.

Additionally, the increasing popularity of energy-efficient manufacturing and sustainability initiatives provides ample opportunity for advanced PLC systems that help monitor and reduce energy consumption across production lines.

Gain a preview of important insights from our Report in this sample - https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=32672

Future Outlook

The future of the programmable logic controller market lies in enhanced interoperability, cloud integration, and edge computing. With greater reliance on smart infrastructure and connected devices, PLCs are expected to evolve into more intelligent, connected controllers.

The incorporation of AI-powered PLCs is expected to revolutionize industrial automation by enabling predictive maintenance, self-diagnosis, and adaptive process control. As PLCs continue to advance, their use will extend beyond industrial sectors into smart cities, transportation systems, and building automation.

Market Segmentation

By Offering:

Hardware: CPU, I/O Modules, Power Supply, Memory System

Software

Services

By Type:

Compact PLC

Modular PLC

Nano, Micro, Small, Medium, and Large PLCs

By Application:

Material Handling

Packaging & Labeling

Process Control

Safety Monitoring

Energy Management

Home & Building Automation

Industrial Equipment Control

By End-use Industry:

Automotive

Energy & Utilities

Food & Beverage

Pharmaceuticals

Construction

Oil & Gas

Semiconductors & Electronics

Regional Insights

Asia Pacific held the largest market share of 36.3% in 2022, led by strong industrial growth in China, Japan, South Korea, and India. The increasing demand for smart manufacturing systems and compact automation solutions in the region is expected to maintain its dominance through 2031.

North America, with a market share of 26.4% in 2022, continues to grow due to early adoption of factory automation and significant investment in smart infrastructure in the U.S. and Canada.

Europe remains a hub for automation technology innovation, with countries like Germany, the U.K., and France focusing on Industry 4.0 implementation across automotive and manufacturing sectors.

Why Buy This Report?

This comprehensive report offers:

Detailed market size, forecast, and growth rate

In-depth competitive landscape and company profiling

Analysis of key market drivers, trends, and opportunities

Region-wise breakdown for strategic decision-making

Porter’s Five Forces, value chain, and trend analysis

Insights into technological developments and their impact

Market segmentation for customized investment strategies

With expert analysis and forward-looking insights, this report serves as a valuable resource for stakeholders, investors, industrial engineers, and policymakers seeking to navigate and capitalize on the fast-evolving programmable logic controller market.

Explore Latest Research Reports by Transparency Market Research: 5G Smart Antenna Market: https://www.transparencymarketresearch.com/5g-smart-antenna-market.html

Solid State Transformer Market: https://www.transparencymarketresearch.com/solid-State-transformer.html

Interactive Display Market: https://www.transparencymarketresearch.com/interactive-display-market.html

GaN Epitaxial Wafers Market: https://www.transparencymarketresearch.com/gan-epitaxial-wafers-market.html

About Transparency Market Research Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information. Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports. Contact: Transparency Market Research Inc. CORPORATE HEADQUARTER DOWNTOWN, 1000 N. West Street, Suite 1200, Wilmington, Delaware 19801 USA Tel: +1-518-618-1030 USA - Canada Toll Free: 866-552-3453 Website: https://www.transparencymarketresearch.com Email: [email protected]

0 notes

Text

Energy & Power Quality Meters Market Drivers Include Grid Modernization, Industrial Automation, and Rising Energy Efficiency Needs

The energy & power quality meters market is witnessing substantial growth, propelled by several dynamic and interconnected drivers that span industries and geographies. As energy systems become more complex and demand for uninterrupted, clean, and efficient power grows, the role of power quality meters becomes increasingly critical. These meters help monitor, manage, and optimize power usage while detecting anomalies that could affect system performance. The market’s expansion is being driven by technological, regulatory, economic, and environmental factors, positioning these meters as indispensable components in modern energy infrastructure.

One of the primary market drivers is grid modernization and the growing need for smart energy management. Power grids across the world are undergoing transformative upgrades to meet the rising demand for renewable integration, distributed generation, and energy storage systems. Power quality meters play a vital role in these smart grid initiatives by providing real-time data on power parameters such as voltage, current, harmonics, and frequency. Utilities rely on this information to detect and address power quality issues, reduce energy losses, and ensure consistent delivery across aging and overloaded infrastructure.

In parallel, the rise of industrial automation and digitization is significantly fueling market demand. Manufacturing plants, data centers, and commercial complexes are deploying advanced power quality meters to enhance process reliability and protect sensitive equipment. Automated systems, including robotics and programmable logic controllers (PLCs), require stable and clean power to function optimally. Even small voltage sags or surges can lead to downtime or equipment damage. Energy and power quality meters provide visibility into power anomalies and trends, allowing timely corrective actions and reducing costly disruptions.

Another critical driver is the increased emphasis on energy efficiency and sustainability. Organizations across sectors are actively seeking ways to optimize their energy usage to lower operational costs and reduce carbon emissions. Power quality meters support these initiatives by offering precise consumption insights, load profiling, and demand tracking. This enables facility managers and energy consultants to identify inefficiencies, correct poor power factor issues, and implement targeted energy-saving strategies. The global push for carbon neutrality and green building certifications further accelerates the deployment of these monitoring tools.

Regulatory mandates and government policies are also pivotal in driving the market forward. Countries across North America, Europe, and Asia-Pacific have implemented standards and incentives that require or encourage the use of energy monitoring systems. These include mandates for energy audits, minimum energy performance standards, and grid compliance requirements. By helping companies meet these regulations and improve energy reporting, power quality meters not only support compliance but also enhance transparency and accountability.

In the commercial and residential sectors, the demand for uninterrupted and quality power is at an all-time high due to the widespread use of electronic devices, HVAC systems, and smart home technologies. As power quality disturbances can damage appliances and reduce energy efficiency, residential and commercial buildings are increasingly integrating power monitoring solutions. This trend is especially noticeable in high-density urban environments and commercial hubs, where energy usage is intense and continuous.

The expansion of renewable energy systems is another major force shaping the market. Solar and wind installations, both on-grid and off-grid, require precise energy flow monitoring to ensure compatibility with the main grid and avoid voltage fluctuations. Power quality meters enable renewable energy developers and operators to manage bidirectional energy flows, maintain grid stability, and optimize output. As renewable energy becomes more mainstream, these meters will play a central role in enabling a smooth and efficient energy transition.

Technological advancements are amplifying these drivers by making power quality meters more intelligent, compact, and affordable. Modern meters now come with features like remote monitoring, cloud integration, wireless communication, and AI-driven analytics. These innovations make it easier for companies of all sizes to deploy and maintain monitoring systems, even across large or distributed operations. The rising adoption of Internet of Things (IoT) platforms in energy management also complements power quality meters by creating interconnected networks for real-time performance visualization and automation.

Lastly, the increasing frequency of power outages, voltage disturbances, and blackouts due to climate change and grid stress is raising awareness of power quality issues. Businesses and utilities alike are prioritizing investments in power quality monitoring to enhance system resilience, ensure continuity, and protect infrastructure. As power becomes more decentralized and digital, the importance of maintaining quality and reliability cannot be overstated.

In conclusion, the drivers behind the energy & power quality meters market are diverse and deeply rooted in the evolving energy landscape. From smart grids and industrial automation to sustainability goals and regulatory compliance, these forces collectively push the market toward rapid innovation and widespread adoption. As the demand for clean, efficient, and stable power grows, power quality meters will remain central to achieving these energy goals.

0 notes

Text

Future of Operational Technology Market: Trends and Predictions

According to a recent report published by Grand View Research, Inc., the global operational technology (OT) market is expected to reach a valuation of USD 364.74 billion by 2030. The market is projected to grow at a compound annual growth rate (CAGR) of 9.6% from 2025 to 2030. This anticipated growth is primarily fueled by the rising demand for robust OT security solutions, which has become increasingly critical due to the growing reliance on digital technologies within industrial environments. As industrial systems become more digitized and interconnected, they become more susceptible to cybersecurity threats, thus heightening the need for fortified protection mechanisms.

One of the key driving forces behind this market trend is the implementation of stringent government regulations focused on cybersecurity. These regulations—such as comprehensive cybersecurity frameworks for Industrial Control Systems (ICS)—mandate that organizations adopt enhanced security protocols to protect their infrastructure. Additionally, as Information Technology (IT) and Operational Technology (OT) systems converge, the lines between corporate and industrial networks blur, creating more entry points for cyber threats to infiltrate OT systems through IT channels. This growing interconnectedness significantly elevates the risk profile, leading to an increased need for resilient and secure OT systems to protect vital industrial operations and ensure business continuity.

Operational technologies refer to the hardware and software systems that are used to monitor, control, and manage physical processes and equipment in real-world environments. These technologies include Distributed Control Systems (DCS), Supervisory Control and Data Acquisition (SCADA) systems, Programmable Logic Controllers (PLCs), Building Management Systems (BMS), Computer Numerical Control (CNC) systems, and more. Such systems play a critical role in managing key infrastructure, including manufacturing plants, power generation stations, and water treatment facilities. By ensuring real-time monitoring and control, OT systems are essential for maintaining operational efficiency, safety, and reliability, and for protecting against system failures and environmental hazards.

The operational technology market is highly dynamic and competitive, with companies continuously adapting to evolving challenges and opportunities. Market participants are heavily investing in research and development to produce innovative solutions that enhance system resilience. The integration of artificial intelligence (AI) and machine learning into OT security offerings is a prominent trend, enabling predictive maintenance, real-time threat detection, and automated response mechanisms.

For example, Huawei Technologies Co., Ltd. is playing a pivotal role in the digital transformation of the manufacturing sector. The company is actively promoting the convergence of Information and Communications Technology (ICT) with Operational Technology, aiming to create smart, interconnected production environments. Huawei's initiatives are closely aligned with major global industrial strategies such as Germany’s Industry 4.0, China’s Made in China 2025, and the U.S. Industrial Internet. Through these efforts, the company is contributing to the modernization of manufacturing ecosystems, fostering digitally integrated, intelligent, and automated industrial processes that are more efficient, adaptive, and secure.

Curious about the Operational Technology Market? Download your FREE sample copy now and get a sneak peek into the latest insights and trends.

Frequently Asked Questions (FAQ) – Global Operational Technology Market

1. What is the projected size of the global operational technology market by 2030?

According to a report by Grand View Research, Inc., the global operational technology market is expected to reach USD 364.74 billion by 2030, growing at a compound annual growth rate (CAGR) of 10% from 2024 to 2030.

2. What factors are driving the growth of the OT market?

The growth of the OT market is driven by several key factors:

• Increased reliance on digital technologies: Industries are adopting digital solutions for enhanced efficiency, leading to a higher demand for OT systems.

• Rising cybersecurity concerns: The growing threat of cyberattacks has heightened the need for robust OT security measures.

• Government regulations: Strict cybersecurity frameworks and policies are compelling organizations to implement comprehensive OT security protocols.

• Integration of IT and OT systems: The convergence of IT and OT increases interconnectedness, exposing OT systems to potential cyber threats.

3. What are operational technologies, and where are they used?

Operational technologies encompass hardware and software systems that monitor and control physical processes in various industries. Examples include:

• Distributed Control Systems (DCS)

• Supervisory Control and Data Acquisition (SCADA) systems

• Programmable Logic Controllers (PLCs)

• Building Management Systems (BMS)

• Computer Numerical Control (CNC) systems

These technologies are integral to critical infrastructure such as manufacturing plants, power stations, and water treatment facilities, ensuring efficient and secure management of industrial processes.

4. Which regions are leading in OT market adoption?

As of 2023, North America dominated the OT market, accounting for approximately 37.7% of the global revenue. The United States is projected to lead the market by 2030, driven by advancements in technologies like the Industrial Internet of Things (IIoT), artificial intelligence (AI), and edge computing.

5. What are the key components driving the OT market?

Key components in the OT market include:

• Computer Numerical Control (CNC) systems: Leading the market with significant revenue, driven by demand across manufacturing, automotive, and aerospace industries.

• Building Management Systems (BMS): Projected to grow at the highest CAGR, fueled by the increasing demand for energy-efficient and sustainable buildings.

Order a free sample PDF of the Operational Technology Market Intelligence Study, published by Grand View Research.

#Operational Technology Market#Operational Technology Market Size#Operational Technology Market Share#Operational Technology Market Analysis

0 notes

Text

"One Institute, Many Opportunities:

Build Your Skills in Marketing, Automation, and AI"

In a world where data and technology rule, upskilling has become crucial for success in contemporary sectors. The chance to learn in-demand skills is now more accessible than ever for professionals and students in Kannur, Kerala. There are currently universities in Kannur that provide state-of-the-art instruction in a variety of fields, whether you want to work as a certified industrial automation engineer, a data scientist, or a digital marketing strategist.

IPCS

The industry-focused courses offered by IPCS Global Kannur, a top technical training center in Kerala, include Digital Marketing, Industrial Automation, BMS (Building Management Systems), CCTV & Security Systems, Python Programming, and Data Science. IPCS Global places a strong emphasis on practical instruction and real-world application to close the knowledge gap between academia and industry demands. With its state-of-the-art laboratories and knowledgeable instructors, the Kannur Center guarantees that students get both academic and real-world experience. With flexible learning options, globally recognized certifications, and committed placement support, IPCS Global Kannur can help you thrive in today's competitive job market, whether you're a professional looking to advance your skills or a student ready to start a career.

Digital Marketing

Every facet of lead generation and online brand creation is covered in the Digital Marketing program.Explore the realms of social media tactics, content marketing, SEO, Google Ads, online branding, and more. With training in real-time projects, campaign management, and analytics tools, our Digital Marketing course is intended to prepare you for the workforce.

What Is Digital Marketing and Why Does It Matter Today?

Businesses can no longer rely exclusively on traditional marketing strategies in the fast-paced, internet-driven world of today. Regardless of your company's size—startup, small, or multinational—your internet presence has the power to create or break your success. Digital marketing is a potent tool for connecting with your audience, building your brand, and achieving results.

What You’ll Learn:

Search Engine Optimization (SEO)

Google Ads & Analytics

Social Media Marketing (SMM)

Content Creation & Strategy

Email & Affiliate Marketing

What Makes Digital Marketing Vital?

Greater Reach

Digital marketing, as opposed to traditional marketing, enables instantaneous worldwide audience reach.

Economical

Online marketing are frequently more measurable and less expensive than print or television advertisements.

Measurable Outcomes

You can make data-driven decisions and monitor performance in real time with tools like Facebook Insights and Google Analytics.

Advertising That Is Targeted

Your ROI can be raised by targeting users according to their location, age, hobbies, behavior, and more.

Enhances Brand Image

Credibility and trust are increased by having a strong online presence. This is influenced by social proof, reviews, and interesting content.

Industrial Automation

From PLC programming to SCADA systems, our Industrial Automation course equips you with the skills needed in the manufacturing, robotics, and process control sectors. See the newest tools and simulations up close.

Speed, accuracy, and efficiency are no more optional in the cutthroat industrial environment of today; they are necessary. Industrial automation is a solution to the problem. Automation is changing how businesses function, from power generation and food packaging to automobile factories, making operations more dependable, intelligent, and safe.

What is Industrial Automation?

Industrial automation is the act of running machinery and processes with little assistance from humans by using control systems like computers, robots, and programmable logic controllers (PLCs). Intelligent systems that are capable of real-time monitoring, control, and optimization of industrial procedures take the place of manual operations.

Key Highlights:

PLC & HMI Programming

SCADA Integration

Electrical & Pneumatic Control Systems

Industrial Sensors & Actuators

BMS (Building Management Systems)

Take control of the clever brain that powers smart buildings! Learn how to manage and keep an eye on energy, fire, lighting, and HVAC systems. Our BMS training can help you become ready for careers in smart infrastructure deployment and facilities management.

The requirement for integrated control and monitoring systems grows as buildings become smarter and more energy-efficient. In order to manage a building's vital services for sustainability, efficiency, and safety, BMS (Building Management Systems) are crucial.

Covered Topics:

HVAC Controls & Integration

Lighting & Access Control

Energy Monitoring

Fire Alarm & Security Systems

CCTV & Surveillance Systems

CCTV installation and maintenance are essential skills given the rising demand for security systems. The technical know-how from system design to installation and remote monitoring is taught in our course.

Course Modules:

Camera Types & Configuration

DVR/NVR Setup

IP vs Analog Systems

Troubleshooting & Maintenance

Python Programming

Learn Python from the ground up—it's perfect for both novices and developers. You will acquire the coding abilities required for automation, web development, and data science through hands-on examples and real-world applications.

One of the most important skills you may have in the digital age is the ability to understand and use data. Whether it is through AI models, consumer behavior analysis, or market trend prediction, data science is revolutionizing every organization. Python, one of the most powerful yet user-friendly programming languages, is at the center of this change.

The goal of data science is to extract meaningful insights from massive volumes of both structured and unstructured data. Combining elements of statistics, machine learning, programming, and data visualization, it resolves complex problems and facilitates decision-making.

Learn To:

Write Efficient Python Code

Build Web Applications

Automate Tasks

Handle File and Data Operations

Data Science

Our Data Science program teaches you how to glean valuable insights from data, which is the new oil. Use Python and industry-standard tools to study data visualization, machine learning, and statistics.

Why Choose IPCS GLOBAL

Experienced Industry Trainers

100% Practical-Oriented Training

Certification Support

Placement Assistance

Flexible Batches (Online & Offline)

CONCLUSION

Whether you're stepping into the world of Industrial Automation, diving into the digital landscape with Digital Marketing, managing smart buildings with BMS, or unlocking the power of Python and Data Science, our hands-on, industry-driven training programs are designed to make you job-ready and future-proof.

With expert instructors, real-time project experience, and strong placement support, IPCS has become a trusted name for quality technical education and professional growth. Join us today and take the first step toward a brighter, smarter future.

Start Your Today!

📞 Call us: 9745396641

🌐 E MAIL ID:[email protected]

Visit website:ipcs

0 notes

Text

Nigeria, Indonesia, and Turkey: The New Frontiers for Oscillating Granulators Market Players

Nigeria, Indonesia, and Turkey are rapidly emerging as high-growth markets within the global Oscillating Granulators industry. With the market currently valued at $439.5 million, these three countries are forecasted to experience compound annual growth rates (CAGR) ranging from 6.1% to 8.7% between 2025 and 2030. This surge is primarily driven by rising demand in pharmaceutical manufacturing and food processing—two industries where granulators are essential for precision granulation and particle size control.

Check detailed insights here - https://datastringconsulting.com/industry-analysis/oscillating-granulators-market-research-report

Expanding Role in Food and Pharmaceutical Sectors

Oscillating granulators are widely utilized in the food processing sector to ensure uniform particle sizes during the size reduction and sieving phases. These machines help maintain the physical integrity of food products during granulation, offering efficiency without compromising quality. Prominent industry names such as GEA Group and Sotuken have successfully integrated oscillating granulators into their food production lines to meet stringent quality standards.

In the pharmaceutical industry, oscillating granulators play a critical role in the formulation process. They ensure consistent granule size for tablet compression and capsule filling, a necessity for dose accuracy and stability. The rising focus on automation and compliance with Good Manufacturing Practices (GMP) continues to propel adoption.

Technological Advancements Driving Efficiency

The global oscillating granulators market is undergoing a digital transformation. The integration of programmable logic controllers (PLCs) has significantly enhanced machine performance. These controllers allow operators to regulate oscillation speed, frequency, and timing with high precision, reducing manual intervention and streamlining production. Moreover, the growing adoption of AI and machine learning in pharmaceutical and chemical granulation processes is optimizing outcomes and enabling predictive maintenance, which enhances machine longevity and minimizes downtime.

Global and Regional Growth Trends

From a global perspective, the Oscillating Granulators market is projected to grow from $439.5 million in 2024 to $1,056.5 million by 2035, reflecting a robust CAGR of 8.3%. North America remains a dominant force in the market, driven by its high-tech pharmaceutical and chemical sectors. The region's demand is shaped by increasing automation, focus on energy-efficient equipment, and the need for compact, high-speed granulators that align with waste reduction goals.

However, competition in North America is intense, with well-established players setting high performance and compliance benchmarks. New entrants face challenges in breaking into the market due to these elevated standards and entrenched supplier relationships.

Industry Landscape and Innovation

Key manufacturers—including GEA Group, SaintyCo, The Elizabeth Companies, Alexanderwerk, Cadmach Machinery, Frewitt Fabrique de machines SA, Chamunda Pharma Machinery, SOTAX Group, and Kevin Process Technologies Pvt. Ltd.—are actively innovating to capture market share. Strategic collaborations, investment in R&D, and an increasing focus on smart granulation systems are key approaches adopted to stay competitive.

Market Segmentation and Use Cases

Oscillating granulators are segmented by product types (horizontal and vertical), applications (pharmaceutical, chemical & fertilizer, food & beverage), and technology types (mechanical and digital). End-users range from research laboratories and pharmaceutical manufacturers to food processing units, reflecting the versatile utility of these machines across industries.

About DataString Consulting

DataString Consulting provides deep market intelligence and strategic insights that help organizations craft successful business roadmaps. With over three decades of combined experience in market research and strategy advisory, DataString supports companies in expanding into new territories, growing their total addressable markets, and diversifying revenue streams. With continuous monitoring across more than 15 industries and 60 sub-sectors, DataString helps businesses cut through the noise and discover new opportunities for innovation, growth, and market penetration.

#OscillatingGranulators#PharmaceuticalMachinery#FoodProcessingEquipment#GranulationTechnology#EmergingMarkets#NigeriaBusiness#IndonesiaIndustry#TurkeyManufacturing#PharmaInnovation#SmartManufacturing#IndustrialAutomation#AIinManufacturing#MachineLearning#ProcessEfficiency#DataStringConsulting#GlobalMarkets#TechInFood#AutomationSolutions#MarketResearch#GrowthMarkets

0 notes

Text

Revolutionizing Monofilament Yarn Manufacturing: Trends and Innovations

Technology continues to shape and enhance every aspect of industrial manufacturing, and monofilament yarn manufacturers are embracing cutting-edge advancements to improve efficiency, sustainability, and accuracy. Modern monofilament yarn-making machines are now capable of producing high-quality yarns used in diverse applications, including ropes, nets, brushes, and fishing lines.

Among the most commonly used yarn types are PET monofilament yarns (polyethylene terephthalate) and PP monofilament yarns (polypropylene). Known for their strength, durability, and versatility, these materials are essential across various industries. With increasing technological progress, monofilament yarn extrusion machines are evolving to meet the growing demands of monofilament yarn manufacturers, ensuring optimal production and superior product quality.

Here are the top trends shaping the future of monofilament yarn production.

Energy-Efficient Monofilament Yarn-Making Machines

Energy efficiency is now a key priority in yarn manufacturing, with industry leaders adopting eco-friendly solutions to minimize energy consumption and reduce costs.

A groundbreaking innovation in sustainable production is the introduction of energy-regenerative units, which replace traditional braking resistors. These systems capture excess heat generated by machinery and convert it into usable power, optimizing energy usage and cutting down on waste.

This transformation highlights a major step toward greener manufacturing, helping businesses reduce carbon footprints while maintaining high output quality.

Enhancing Efficiency and Accuracy

With increased global demand, efficiency and precision in yarn production have become critical. Manufacturers are now integrating PLC (Programmable Logic Controller) central control systems, which significantly improve operational accuracy.

These advanced control systems offer:

Remote monitoring and automation – allowing manufacturers to track machine performance in real-time.

Improved production yields – optimizing resource usage and minimizing material waste.

Seamless integration with office computers and HMI systems – enabling 24/7 factory surveillance, even with limited manpower.

This technology has streamlined machinery installation, troubleshooting, and training, enhancing productivity while ensuring high-precision production.

Customized Yarn-Making Solutions

To better serve diverse market needs, manufacturers are shifting toward customized, flexible solutions in monofilament yarn production.

By adopting tailored approaches, manufacturers can:

Improve efficiency, optimizing operations and reducing lead times.

Enhance product quality, ensuring yarns meet specific industry standards.

Adapt to evolving customer demands, remaining competitive in the global market.

This trend toward personalized manufacturing allows monofilament yarn manufacturers to boost productivity while maintaining high-quality output.

Embracing Industry 4.0 Technologies

The future of monofilament yarn production is centered around Industry 4.0 innovations, including:

IoT-enabled automation

Production processing management

Real-time data storage & analysis

Automated machine control

These advancements allow manufacturers to monitor production conditions in real time, ensuring greater precision, lower waste, and optimized performance. By leveraging data-driven insights, businesses can achieve better efficiency and scalability in monofilament yarn extrusion.

Must-Have Features in Next-Generation Yarn-Making Machines

As demand for high-quality monofilament yarn continues to grow, manufacturers must ensure their machinery includes advanced features for efficient, seamless production.

Modern yarn-making machines should incorporate:

Energy-saving technology – optimizing electricity usage and reducing operating costs.

Enhanced data storage & analysis – providing insights into production efficiency and material handling.

Automated control systems – streamlining production and minimizing manual intervention.

Real-time monitoring capabilities – ensuring precision in output and troubleshooting.

Additionally, ensuring compatibility with multiple materials—including recycled PP, HDPE, PA, PET materials, and PET flakes—is crucial for sustainable, eco-friendly production.

Conclusion: Advancing Monofilament Yarn Production

The monofilament yarn extrusion industry is rapidly evolving, embracing automation, customization, and sustainability to enhance manufacturing efficiency. With the integration of smart machinery, energy-efficient solutions, and data-driven innovations, monofilament yarn manufacturers are paving the way for higher-quality, cost-effective production.

Investing in cutting-edge monofilament yarn-making machines ensures manufacturers stay competitive, reducing costs while optimizing output and product precision.

Are you ready to upgrade your yarn production line? Consider these must-have features when selecting high-performance extrusion machines for maximum efficiency and seamless operation.

0 notes

Text

Burn-off Oven Market: Trends, Opportunities, and Growth Outlook

The burn-off oven market is witnessing notable growth due to increasing demand across a wide range of industries such as automotive, aerospace, manufacturing, and metal processing. These ovens, also known as pyrolysis or stripping ovens, are essential for removing paints, varnishes, resins, and other contaminants from metal components through thermal decomposition. As industries seek environmentally friendly and efficient cleaning solutions, burn-off ovens offer a compelling alternative to chemical-based methods.

Market Overview

Burn-off ovens operate by heating components to high temperatures in a controlled environment, where organic materials are vaporized or oxidized, leaving behind clean metal. These ovens are highly effective for cleaning fixtures, engine parts, electric motor housings, and paint hooks, among others. The market has expanded significantly in recent years, thanks to stringent environmental regulations and the increasing importance of sustainability in industrial processes.

Key Market Drivers

Environmental Regulations: Regulatory agencies worldwide are imposing strict restrictions on the use of solvents and other chemical cleaning methods. Burn-off ovens provide a compliant and eco-friendly solution, reducing the need for hazardous waste disposal.

Industrial Automation and Efficiency: With rising emphasis on process automation and efficiency, manufacturers are adopting burn-off ovens for their ability to deliver consistent and thorough cleaning without damaging components.

Growth in End-User Industries: Rapid expansion of the automotive and aerospace sectors, particularly in emerging markets, is boosting demand for maintenance and part-reconditioning solutions—further fueling the adoption of burn-off ovens.

Sustainability Goals: Many industries are focusing on reducing their carbon footprint. Burn-off ovens, when equipped with afterburners and pollution control systems, help achieve lower emissions compared to traditional methods.

Market Segmentation

The burn-off oven market can be segmented based on product type, end-user industry, and geography:

By Type:

Gas-fired ovens

Electric ovens

Infrared ovens

By Application:

Automotive

Aerospace

Electronics

Manufacturing

Recycling

By Region:

North America

Europe

Asia-Pacific

Latin America

Middle East & Africa

Regional Insights

North America currently dominates the burn-off oven market, with a significant presence of automotive and industrial equipment manufacturers. The U.S. is leading due to advanced infrastructure, technological adoption, and environmental policies.

Europe follows closely, driven by stringent EU environmental laws and a focus on sustainable industrial practices. Countries like Germany, Italy, and France are key contributors to the regional market.

Asia-Pacific is expected to witness the fastest growth in the coming years. Countries such as China, India, and Japan are investing heavily in manufacturing and infrastructure, thereby increasing demand for efficient and eco-friendly cleaning technologies.

Competitive Landscape

The market is moderately fragmented, with several global and regional players competing on the basis of technology, energy efficiency, customization, and price. Key players are investing in R&D to develop advanced ovens that consume less energy, offer faster cleaning cycles, and comply with evolving regulations.

Prominent players include:

Pollution Control Products Co.

CEC Combustion Safety

Steelman Industries

ACE Equipment Company

Process Manufacturing Inc.

Technological Advancements

Modern burn-off ovens come with programmable logic controllers (PLCs), touchscreen interfaces, and real-time temperature monitoring for better control and safety. Additionally, energy recovery systems are being integrated to reduce operational costs and environmental impact.

Innovations also include multi-chamber ovens, which allow different cleaning processes to run simultaneously—improving throughput and productivity.

Market Challenges

Despite strong growth prospects, the market faces several challenges:

High Initial Cost: Installation and customization of industrial-grade burn-off ovens require significant capital investment.

Operational Safety: Without proper safety protocols, high-temperature ovens can pose risks to operators.

Emission Compliance: Although cleaner than chemical alternatives, burn-off ovens must be equipped with afterburners and filters to meet emission standards.

Future Outlook

The future of the burn-off oven market looks promising, with growing emphasis on clean manufacturing and sustainable processes. Key opportunities lie in:

Developing compact and mobile burn-off ovens for smaller workshops.

Enhancing automation for minimal human intervention.

Expanding into untapped markets in Africa and Latin America.

Additionally, partnerships between oven manufacturers and industrial service providers can create new business models, including rental services and on-demand cleaning.

Conclusion

The burn-off oven market is evolving rapidly, driven by regulatory pressures, industry demand for efficient cleaning methods, and the global push for sustainable manufacturing. As technology advances and new markets emerge, burn-off ovens are poised to play an even greater role in the industrial ecosystem. Stakeholders who invest in innovation and adaptability will be best positioned to capitalize on the growing demand.

0 notes

Text

Automation Programming in Edwardsville, Illinois | Smarter Industrial Control

Automation programming involves developing the software and logic that controls machines, equipment, and production lines. It’s the “brain” behind any automated system, enabling precise, repeatable, and adaptable actions without constant human intervention.

Key components include:

PLC Programming: Writing logic-based code to control equipment such as motors, sensors, and actuators.

HMI Design: Developing visual interfaces that operators use to monitor and interact with automated systems.

SCADA Integration: Supervisory control systems that collect and analyze data from across an entire facility.

Custom Automation Scripts: Logic tailored to unique processes and workflows.

In Edwardsville, automation programming is essential for companies that want to minimize downtime, improve product quality, and remain competitive.

Why Automation Programming Matters for Edwardsville

With its strong economic base and proximity to major markets like St. Louis, Edwardsville is home to a growing number of industrial operations. Whether it's a mid-sized packaging firm or a large-scale manufacturer, local businesses face increasing pressure to improve efficiency and throughput. That’s where automation programming comes in.

1. Operational Efficiency: Well-programmed systems eliminate manual tasks, speed up production, and reduce the likelihood of human error.

2. Quality Control: Automation ensures consistency across batches, helping companies meet strict quality standards.

3. Cost Savings: By reducing labor costs and minimizing material waste, automation delivers a strong return on investment.

4. Data Utilization: Modern systems provide actionable data insights, allowing operators and managers to make smarter decisions in real-time.

In Edwardsville, this translates into better-performing factories, safer work environments, and increased economic resilience.

Core Services Provided by Automation Programmers

Local automation programming companies in Edwardsville offer a range of services to support manufacturers across sectors. These include:

Custom PLC Programming: Tailored logic to manage specific machines or entire production lines.

HMI Interface Development: Easy-to-use control panels that display system data and allow for quick troubleshooting.

SCADA System Setup: Centralized control systems that integrate data from multiple sources.

Retrofit and Upgrade Services: Modernizing older machines with new control logic and communication protocols.

Process Optimization: Using analytics and automation logic to fine-tune production flow.

These services ensure systems operate at peak performance, even in complex, multi-stage production environments.

Industries in Edwardsville Benefiting from Automation Programming

Automation programming is not limited to one field. It plays a critical role across many Edwardsville industries:

Food & Beverage: Automating mixing, filling, and packaging for hygiene and speed.

Warehousing & Logistics: Conveyor control and sorting systems that reduce shipping delays.

Pharmaceuticals: Precision dosing and environmental controls for product safety.

Automotive Components: Robotic assembly coordination and inspection programming.

Metal Fabrication: CNC machine integration and real-time production monitoring.

These industries depend on accurate, flexible programming to respond to market demands while maintaining operational control.

Tools and Platforms Used in Edwardsville

Automation programming professionals in Edwardsville are proficient in a wide range of technologies and platforms, including:

Allen-Bradley / Rockwell Automation

Siemens TIA Portal

Mitsubishi PLCs

Omron and ABB Systems

Ignition SCADA

Wonderware (AVEVA)

Beckhoff TwinCAT

These platforms offer robust tools for machine control, process visualization, and data management—all essential for high-performance automation systems.

Workforce Training and Local Support

Edwardsville benefits from strong academic institutions like Southern Illinois University Edwardsville (SIUE), which offers programs in engineering, computer science, and industrial technology. These institutions help build a local talent pipeline of engineers and programmers equipped to design and maintain next-generation automation systems.

Additionally, ongoing partnerships between automation companies and local manufacturers ensure that workforce development aligns with real-world needs. On-the-job training and technical certifications are increasingly available to support career growth in automation programming.

Looking Ahead: Smarter Factories on the Horizon

With the rise of Industry 4.0, the future of manufacturing in Edwardsville is smart, connected, and data-driven. Automation programming is a key enabler of this future. Companies are beginning to adopt:

Remote Monitoring and Control

Cloud-Based Data Storage and Analytics

AI-Enhanced Predictive Maintenance

Digital Twin Simulations

These technologies offer unprecedented visibility and flexibility, allowing businesses to operate more efficiently and react quickly to changes in demand or supply chain conditions.

Your Edwardsville Automation Partner: Xtreme Automation LLC

If you're seeking professional automation programming services in Edwardsville, turn to the experts at Xtreme Automation LLC. With deep experience in PLC programming, HMI development, SCADA integration, and smart system upgrades, Xtreme Automation delivers tailored solutions that boost performance and cut downtime. Whether you're building a new line or upgrading legacy systems, their team ensures seamless automation from design to deployment. Learn more at xtremeautomationllc.com.

#Automation Programming Edwardsville IL#PLC Programming Services Illinois#Industrial Automation Edwardsville#HMI Systems Integration#Custom Control Systems Illinois#Manufacturing Automation Solutions#Programmable Logic Controllers#SCADA Systems Edwardsville#Industrial Software Engineering#Automation Services Metro East IL

0 notes

Text

💡 Revolutionizing Industrial & Marine Automation: How Ram Automations is Redefining the Future

In today’s rapidly evolving industrial and marine sectors, automation isn’t just a luxury—it’s a necessity. As businesses strive for efficiency, Ram Automations stands at the forefront, delivering cutting-edge solutions that drive productivity, minimize downtime, and enhance overall performance.

🔄 The Shift Towards Intelligent Automation

The global shift towards smart automation has transformed the way industries operate. Traditional methods are being replaced by AI-powered systems, IoT-enabled devices, and high-performance industrial control solutions. Ram Automations offers an extensive range of automation components, from programmable logic controllers (PLCs) and human-machine interfaces (HMIs) to precision sensors and industrial-grade motors, ensuring seamless operations across diverse sectors.

⚓ Advanced Marine Automation: Enhancing Safety & Efficiency

Maritime operations demand uncompromised reliability. Ram Automations provides high-end marine automation products such as pressure transmitters, navigation control systems, flame detectors, and power management solutions. These technologies ensure efficient vessel operations, reduce manual intervention, and significantly improve maritime safety standards.

📈 Data-Driven Decision Making: Maximizing Productivity

One of the biggest advantages of modern automation is real-time data analysis. With advanced monitoring and control solutions, businesses can:

Optimize resource allocation

Predict maintenance needs

Reduce unexpected breakdowns

Improve energy efficiency

Ram Automations’ smart solutions empower industries with actionable insights, enabling data-driven decision-making for sustainable business growth.

⚙️ The Competitive Edge: Why Choose Ram Automations?

Trusted Global Supplier – Offering 1,000+ brands with authentic, high-quality parts.

Seamless Integration – Ensuring compatibility with existing systems for effortless automation.

Cost-Effective Solutions – Enhancing efficiency without exceeding budgets.

Rapid Worldwide Shipping – Reliable logistics support to keep operations running smoothly.

Expert Consultation – Professional guidance tailored to industry-specific needs.

✨ Embrace the Future of Automation Today!

Industrial and marine automation is no longer an option—it’s the key to survival in a competitive market. Whether upgrading existing systems or building from the ground up, Ram Automations is your go-to partner for premium automation solutions.

📍 Explore the latest innovations today! Visit Ram Automations 🔗

0 notes

Text

Automation Components: Revolutionizing Industrial Processes

The industrial sector is undergoing a transformation, driven by the increasing adoption of automation technology. Automation components are at the heart of this revolution, enabling industries to streamline operations, enhance efficiency, and achieve unprecedented levels of precision. As a leading provider of innovative automation solutions, Dropship Automation is proud to offer a range of components that help businesses take advantage of these advancements.

Automation components are the building blocks that make automated systems function seamlessly. These components, including sensors, controllers, actuators, drives, and robotic systems, work together to reduce the need for manual labor while optimizing productivity. The integration of such components into industrial environments has become essential for businesses aiming to remain competitive in a fast-paced market.

One of the primary benefits of automation components is the ability to increase operational efficiency. With automated systems in place, industries can complete tasks faster and more accurately than manual processes allow. This translates to higher production rates, fewer errors, and reduced labor costs. Automation components such as programmable logic controllers (PLCs) and advanced sensors provide real-time data, allowing for precise control and monitoring of machinery, ensuring that everything runs smoothly without human intervention.

At Dropship Automation, we specialize in providing high-quality automation components tailored to meet the specific needs of various industries, including manufacturing, automotive, and pharmaceuticals. Our advanced sensors, for example, detect environmental changes and provide instant feedback to the system, ensuring accuracy and consistency. Our actuators and robotic arms handle repetitive tasks such as assembly, material transport, and packaging, allowing human workers to focus on tasks that require greater creativity and problem-solving skills.

The use of automation components also has a significant impact on safety in industrial settings. Automated systems can take on hazardous tasks, such as working with dangerous chemicals or operating heavy machinery, reducing the risk of workplace accidents and improving overall worker safety. Furthermore, automation allows for continuous operation, reducing downtime and maximizing production output.

One of the greatest advantages of automation is its ability to provide data-driven insights. Automation systems continuously gather data on performance, efficiency, and potential issues. This data helps businesses make informed decisions about maintenance, process improvements, and resource allocation, leading to better overall operations.

In conclusion, automation components are transforming industries by providing businesses with tools to improve efficiency, safety, and productivity. As industries continue to evolve, the need for advanced automation solutions grows. At Dropship Automation, we are dedicated to helping businesses integrate automation components that not only drive operational excellence but also pave the way for innovation and growth. Let us partner with you to revolutionize your industrial processes with cutting-edge automation technology.

1 note

·

View note

Text

Global SPC Market to Hit $1.17 Billion by 2035: Here’s Why It Matters

The global Safety Programmable Controller (SPC) market, valued at USD 524.29 million in 2024, is poised for substantial expansion, projected to reach USD 1,171.66 million by 2035. This growth trajectory reflects a robust compound annual growth rate (CAGR) of 7.40% during the forecast period from 2025 to 2035, driven by rising safety demands, stringent regulatory frameworks, and increasing industrial automation.

Market Overview

A Safety Programmable Controller (SPC) is an advanced industrial control device designed specifically to manage safety-critical operations. Unlike standard programmable logic controllers (PLCs), SPCs comply with international safety standards such as IEC 61508 and ISO 13849, making them essential components in modern industrial settings. They control emergency stops, monitor safety light curtains, and manage safety interlocks with redundancy and self-diagnostics to minimize failure risks.

The flexibility of SPCs makes them indispensable across industries such as automotive, oil & gas, chemicals, food processing, and pharmaceuticals, where process safety and operational continuity are vital.

Market Drivers & Trends

1. Rising Industrial Automation

The global shift toward automation in manufacturing and process industries is a significant driver. As industrial operations become more complex and high-powered, the risk of workplace accidents also increases. SPCs ensure safe machine operation by continuously monitoring critical systems and initiating emergency responses when necessary.

2. Government Regulations and Safety Standards

With regulations such as OSHA, IEC 62061, and ISO 13849 becoming more stringent, industries are compelled to integrate advanced safety systems. SPCs are being adopted to maintain compliance and avoid costly penalties or operational shutdowns.

3. Integration with Industry 4.0 and IoT

The adoption of Industry 4.0 technologies and IoT is driving the demand for smart, connected safety systems. SPCs offer real-time data analytics and predictive maintenance capabilities, enhancing both safety and productivity.

Latest Market Trends

Miniaturization and Modular Design: The demand for compact safety PLCs is increasing, especially among SMEs seeking cost-effective solutions.

Real-time Monitoring: With the integration of IoT, SPCs now feature real-time diagnostics and alerts, allowing immediate response to hazards.

Customized Safety Solutions: Tailored solutions for industries like oil & gas and pharmaceuticals are gaining traction, with modular systems that scale as per need.

Gain a preview of important insights from our Report in this sample

Key Players and Industry Leaders

The market landscape is highly competitive and features key players such as:

Siemens AG

Schneider Electric SE

Rockwell Automation, Inc.

Mitsubishi Electric Corporation

ABB Ltd.

Honeywell International Inc.

IDEC Corporation

Keyence Corporation

Pilz GmbH & Co. KG

IFM Electronic GmbH

Sick AG

Omron Corporation

HIMA Group

These companies are investing in R&D, product innovation, and strategic collaborations to expand their market share and enhance global footprints.

Recent Developments

January 2025: IDEC launched the FS1B Safety Controller, offering improved configuration tools and system performance for high-risk industrial applications.

April 2024: IFM Electronic introduced a modular safety controller with enhanced communication capabilities, aimed at complex industrial setups requiring flexible and scalable safety solutions.

Market Opportunities

Emerging Economies: Rapid industrialization in countries like India, Brazil, and Vietnam presents significant growth opportunities for SPC providers.

Adoption in Non-traditional Sectors: Expansion into sectors such as renewable energy, utilities, and smart infrastructure will open new avenues.

Cybersecurity Integration: As cyber-physical systems grow, secure SPCs integrated with advanced cybersecurity measures are becoming increasingly desirable.

Future Outlook

The Safety Programmable Controller market is set for continuous growth, fueled by the increasing need for safe, compliant, and efficient industrial systems. The future will likely see cloud-enabled SPCs, AI-integrated safety systems, and enhanced interoperability across factory floors.

By 2035, the market will not only double in size but also transform in functionality, offering predictive, preventive, and connected safety solutions tailored to smart industrial ecosystems.

Market Segmentation

By Type:

Modular Safety PLC

Compact Safety PLC

By Application:

Assembly

Material Handling

Metal Working

Packaging

Robotics

Others (Welding, Shielding, etc.)

By End-use Industry:

Process Industries (56.90% share in 2024)

Chemicals

Food & Beverages

Metals & Mining

Oil & Gas

Pharmaceuticals

Pulp & Paper

Others

Discrete Industries

Automotive

Aerospace and Defense

Semiconductor and Electronics

Healthcare

Others

By Sales Channel:

Direct

Indirect

Regional Insights

East Asia led the market in 2024, capturing 29.88% of global revenue. The region benefits from:

A strong industrial base in China, Japan, and South Korea

Government-driven safety mandates

Rapid automation and adoption of Industry 4.0

North America and Western Europe follow closely due to well-established manufacturing sectors and early adoption of automation technologies.

Emerging regions such as South Asia, Middle East, and South America are anticipated to grow rapidly due to increasing awareness, infrastructure development, and foreign direct investments in manufacturing.

Frequently Asked Questions (FAQs)

Q1: What is the current size of the Safety Programmable Controller market? A1: As of 2024, the market is valued at US$ 524.29 million.

Q2: What is the expected market size by 2035? A2: The market is projected to reach US$ 1,171.66 million by 2035.

Q3: What CAGR is the market expected to register? A3: The market is forecast to grow at a CAGR of 7.40% from 2025 to 2035.

Q4: Which region dominates the global market? A4: East Asia, led by China, dominates with a 29.88% share in 2024.

Q5: Who are the leading players in the market? A5: Key players include Siemens, Schneider Electric, Rockwell Automation, ABB, Mitsubishi Electric, Omron, and Honeywell.

Q6: What are the key drivers of market growth? A6: Rising industrial automation, stricter safety regulations, and integration with Industry 4.0 and IoT.

Explore Latest Research Reports by Transparency Market Research: Nano Positioning Systems Market

Wireless Access Control Market

EMC Shielding and Test Equipment Market

Load Cell Market

About Transparency Market Research Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information. Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports. Contact: Transparency Market Research Inc. CORPORATE HEADQUARTER DOWNTOWN, 1000 N. West Street, Suite 1200, Wilmington, Delaware 19801 USA Tel: +1-518-618-1030 USA - Canada Toll Free: 866-552-3453 Website: https://www.transparencymarketresearch.com Email: [email protected]

0 notes

Text

The Impact of Automation on Roller Conveyor Systems in the UK

In the fast-paced world of manufacturing, warehousing, and logistics, automation is reshaping industries worldwide. In the UK, one area experiencing significant transformation is roller conveyor systems. By integrating cutting-edge automation technologies, companies are achieving greater efficiency, safety, and cost-effectiveness. This blog explores how automation is revolutionizing roller conveyor systems across the UK and the benefits it brings to businesses.

Automation in Roller Conveyor Systems: An Overview

Automation in roller conveyor systems refers to the use of advanced technology, such as sensors, motors, and control systems, to streamline material handling processes. Instead of manual intervention, automated systems handle tasks such as loading, transferring, and sorting materials, making operations faster and more reliable.

In the UK, this shift has been driven by the need for greater productivity and the rising demand for flexible, scalable solutions in industries like e-commerce, food production, and automotive manufacturing.

Key Impacts of Automation on Roller Conveyor Systems

Enhanced Efficiency Automated roller conveyor systems significantly improve material handling efficiency. By incorporating technologies such as programmable logic controllers (PLCs), these systems can optimize the speed, direction, and flow of goods. This reduces bottlenecks and ensures seamless operations, even in high-volume environments like warehouses and distribution centers.

Cost Savings Although the initial investment in automation may be high, the long-term cost savings are undeniable. Automated systems minimize human error, reduce labor costs, and lower maintenance expenses. For UK businesses competing in a global market, this translates to higher profit margins.